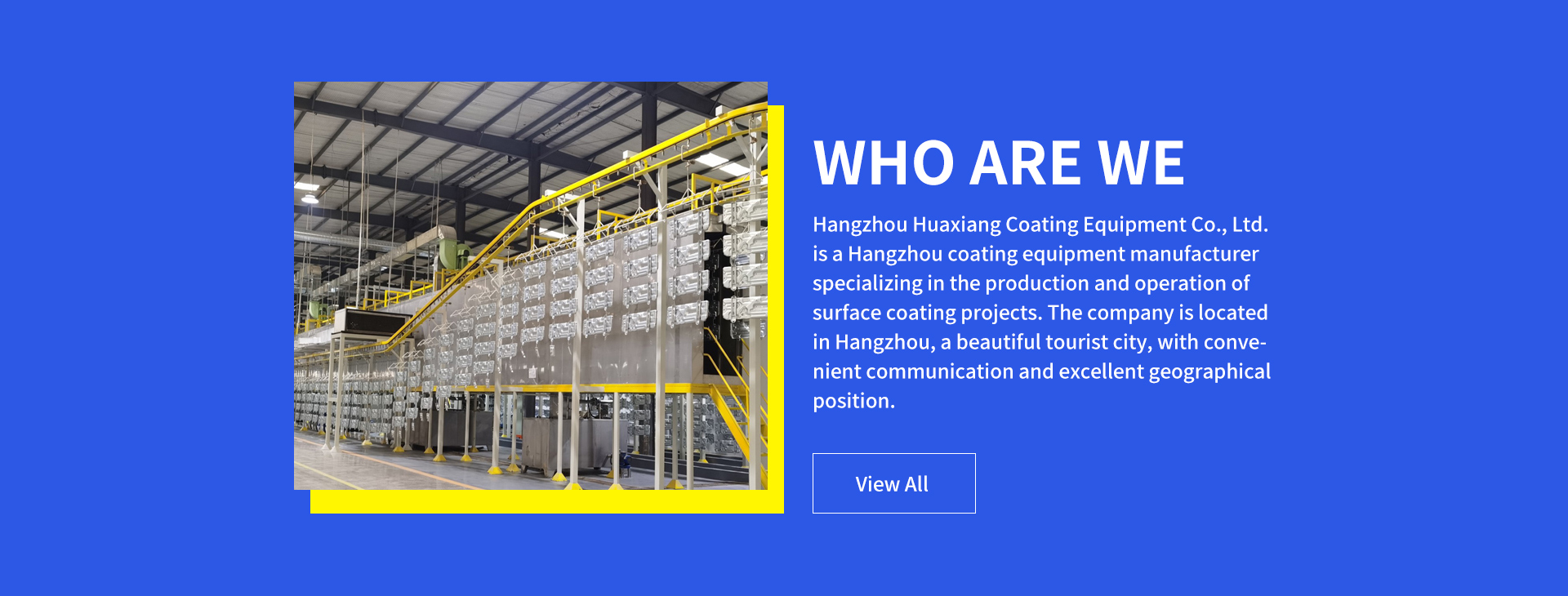

1. Industrial Powder Spraying Booth Overview and Components

An Industrial Powder Spraying Booth is a controlled workspace designed to contain and manage powder coating processes. Key components include a ventilated enclosure, high-efficiency filtration system (e.g., cartridge filters or cyclones), powder recovery units, airflow regulators, and LED lighting. The booth ensures overspray containment, clean air circulation, and operator safety. Durable materials like stainless steel or powder-coated mild steel enhance longevity, while modular designs allow customization for various production scales.

2. Applications of Industrial Powder Spraying Booth

These booths are essential in automotive repair, metal fabrication, appliance manufacturing, and aerospace industries. They are used to coat car parts, machinery components, household appliances, and structural steel. Suitable for materials like aluminum, steel, and heat-resistant plastics, they ensure uniform, high-quality finishes while minimizing environmental contamination.

3. Pricing of Industrial Powder Spraying Booth

Prices range from 4,000forbasicmanualboothsto120,000+ for automated systems with advanced features. Entry-level models suit small workshops, while large-scale booths with HEPA filters, IoT monitoring, and conveyor integration cater to industrial facilities. Factors like size, airflow capacity, and compliance with safety standards (e.g., OSHA, EPA) affect costs.

4. Proper Usage of Industrial Powder Spraying Booth

Setup: Ensure proper grounding and ventilation before operation.

Pre-Spray Checks: Inspect filters and clean the booth interior.

Spraying: Maintain consistent airflow (100–150 ft/min) to capture overspray.

Recovery: Use integrated cyclones to recycle 90%+ excess powder.

Post-Process: Dispose of waste safely and clean surfaces to prevent cross-contamination.

5. How to Choose an Industrial Powder Spraying Booth

Size: Select a booth 1.5x the size of your largest workpiece.

Filtration: Opt for ≥98% efficiency filters to meet regulatory standards.

Material: Stainless steel resists corrosion; galvanized steel is cost-effective.

Automation: Choose conveyor-enabled booths for high-volume production.

6. Safety Precautions for Industrial Powder Spraying Booth

Wear NIOSH-approved respirators, gloves, and anti-static clothing.

Install explosion-proof lighting and ventilation in combustible environments.

Regularly test airflow velocity and filter integrity.

Ground all equipment to prevent electrostatic discharge.

7. Design Rationale of Industrial Powder Spraying Booth

Modern booths prioritize safety, efficiency, and sustainability. Anti-static coatings prevent powder buildup, while energy-efficient fans reduce power consumption. Modular panels enable easy expansion, and IoT sensors monitor air quality in real time.

8. Q&A on Industrial Powder Spraying Booth

Q1: How often should I replace booth filters?

A: Replace every 3–6 months, depending on usage and powder type.

Q2: Can these booths handle high-temperature powders?

A: Yes, if the booth’s materials and ventilation system are heat-resistant.

Q3: What airflow speed ensures optimal powder containment?

A: Maintain 120–150 ft/min to capture overspray effectively.

Q4: Are powder recovery systems worth the investment?

A: Yes, recycling 85–95% of powder reduces material costs by 40%.

Q5: Is professional installation necessary?

A: Yes, to ensure compliance with safety and electrical codes.

This guide provides critical insights into Industrial Powder Spraying Booths, helping businesses optimize coating quality, safety, and operational efficiency.

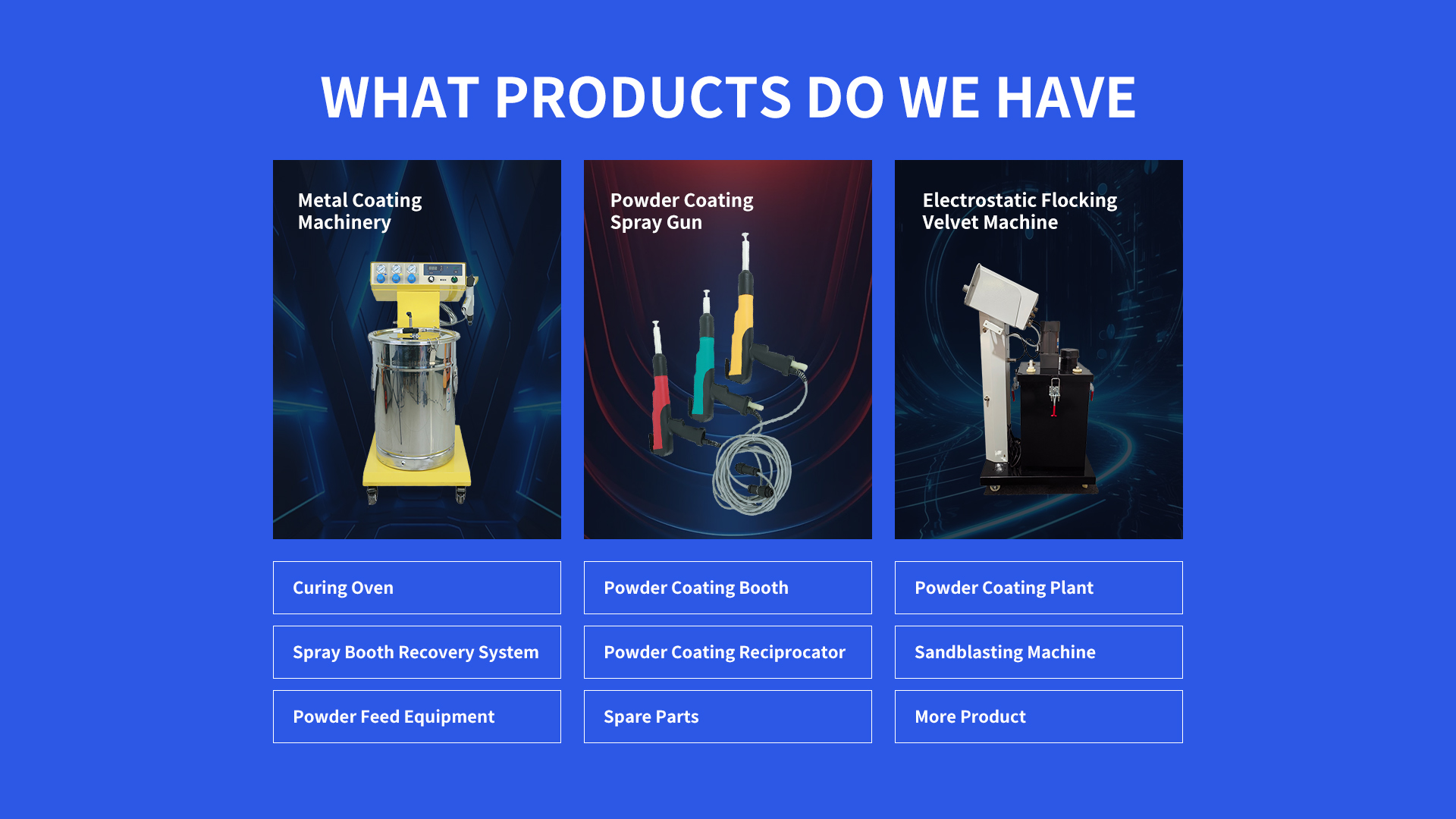

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com